|

|

Current Rating Up To 30A Electrical Wire Harness Assembly Featuring Teflon Insulation Material Suitable for Automotive and Electronic Systems

Product Details:

Payment & Shipping Terms:

|

| Connector Type: | Crimp, Solder, Or Plug-in | Wire Gauge: | 10 AWG To 26 AWG |

|---|---|---|---|

| Flexibility: | Flexible Or Semi-Rigid | Length: | Customizable, Typically 10cm To 5m |

| Application: | Automotive, Electronics, Appliances, Industrial Equipment | Material: | Copper, Aluminum, Or Alloy |

| Voltage Rating: | 300V To 600V | Insulation Material: | PVC, PE, Teflon, Or Rubber |

| Terminal Wire: | BH 3.5mm Pitch White Rabbit Male And Female Plug-in Terminal Wire, Air Connection, Free Sample Making. |

Product Description:

The Terminal Wire / Wire Harness product is a crucial component designed to streamline and enhance the connectivity in various electrical and electronic applications. Renowned for its reliability and versatility, this product serves as an essential part of Electrical Wire Harness Assemblies used across multiple industries, including automotive, electronics, appliances, and industrial equipment.

At the core of the Terminal Wire / Wire Harness is its construction material, which can be copper, aluminum, or a specialized alloy. These high-quality materials ensure excellent electrical conductivity and mechanical strength, making the wire harness capable of handling a wide range of electrical loads. Copper, known for its superior conductivity, is commonly used in applications requiring low resistance and high efficiency. Aluminum offers a lightweight and cost-effective alternative, while alloy options provide enhanced durability and corrosion resistance, catering to environments with demanding conditions.

This product is designed to operate within a voltage rating ranging from 300V to 600V, making it suitable for a broad spectrum of applications. Whether it’s powering delicate electronic devices or supporting heavy-duty industrial machinery, the Terminal Wire / Wire Harness can withstand the electrical demands and maintain optimal performance. This voltage range ensures compatibility with most standard electrical systems found in automotive, electronics, appliances, and industrial equipment sectors.

Another significant attribute of this wire harness is the availability of shielding options. Customers can choose between versions with or without shielding based on their specific application requirements. Shielded wire harnesses provide enhanced protection against electromagnetic interference (EMI) and radio-frequency interference (RFI), which is critical in sensitive electronic environments. This shielding capability ensures signal integrity and reduces noise, thereby improving the overall reliability of the Industrial Wire Harness System. On the other hand, unshielded versions offer a cost-effective solution where interference is not a concern, without compromising on the fundamental performance of the wire harness assembly.

The insulation material used in the Terminal Wire / Wire Harness product is carefully selected to provide maximum safety, flexibility, and durability. Options include PVC (Polyvinyl Chloride), PE (Polyethylene), Teflon, or Rubber. PVC insulation is widely used due to its excellent flame retardant properties, affordability, and good mechanical strength. PE insulation provides superior moisture resistance and is ideal for applications exposed to harsh environmental conditions. Teflon insulation is known for its high-temperature resistance and chemical inertness, making it suitable for high-performance and specialized industrial applications. Rubber insulation offers excellent flexibility and resilience, especially in dynamic environments where constant movement or vibration is expected.

The versatility of this Terminal Wire / Wire Harness product makes it an indispensable part of any Electrical Wire Harness Assembly. Its adaptability across automotive systems helps in managing complex wiring networks in vehicles, ensuring safety and efficiency. In electronics, it facilitates the compact and organized routing of wires, contributing to the miniaturization and enhanced functionality of devices. For household and commercial appliances, the wire harness ensures reliable electrical connections that withstand everyday use. In industrial equipment, it supports robust and durable wiring solutions capable of operating in challenging conditions, making it a vital element of any Industrial Wire Harness System.

In summary, the Terminal Wire / Wire Harness product is engineered with precision and quality materials to meet the demanding needs of various industries. Its wide application range, robust material options, flexible insulation choices, and shielding availability make it a versatile and dependable solution for electrical wiring needs. Whether used in an Electrical Wire Harness Assembly for automotive or industrial purposes, this product guarantees enhanced performance, safety, and longevity, solidifying its place as a key component in modern electrical systems.

Features:

- Product Name: Terminal Wire / Wire Harness

- Shielding: Available with or without shielding for enhanced protection

- Material: Made from high-quality copper, aluminum, or alloy

- Color Options: Red, Black, Blue, Yellow, Green, and more

- Length: Customizable lengths, typically ranging from 10cm to 5m

- Insulation Material: PVC, PE, Teflon, or rubber insulation for durability and safety

- Provides a reliable Electrical Wire Harness Assembly for various applications

- Offers a Custom Wire Harness Solution tailored to your specific requirements

- Ideal for use in Electrical Wire Harness Assembly to ensure efficient electrical connectivity

Technical Parameters:

| Wire Gauge | 10 AWG To 26 AWG |

| Insulation Material | PVC, PE, Teflon, Or Rubber |

| Temperature Range | -40°C To 105°C |

| Connector Type | Crimp, Solder, Or Plug-in |

| Current Rating | Up To 30A |

| Color | Red, Black, Blue, Yellow, Green, Etc. |

| Shielding | Available With Or Without Shielding |

| Length | Customizable, Typically 10cm To 5m |

| Voltage Rating | 300V To 600V |

| Flexibility | Flexible Or Semi-Rigid |

Applications:

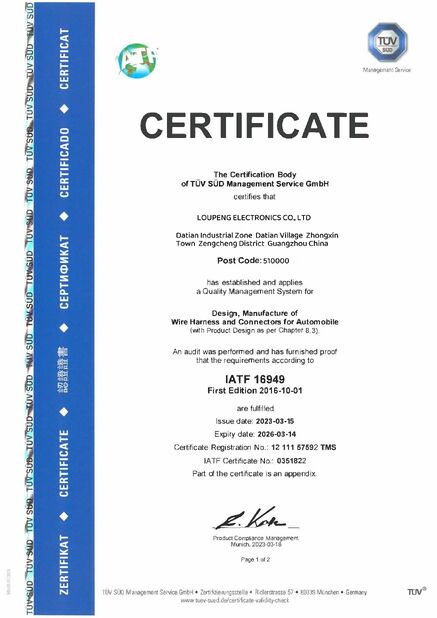

The LP Terminal Wire / Wire Harness, model number LP-TW010, is a high-quality product originating from China and certified under ISO-9001:2000 standards. Designed with precision and durability in mind, this wire harness is ideal for a wide range of applications, including automotive, electronics, appliances, and industrial equipment. Its versatile construction using materials such as copper, aluminum, or alloy ensures reliable conductivity and long-lasting performance, accommodating current ratings of up to 30A.

One of the primary application occasions for the LP Terminal Wire Harness is in the automotive industry. The Automotive Wiring Harness is essential for connecting various electrical components within vehicles, ensuring efficient power distribution and signal transmission. Whether it’s used in passenger cars, commercial trucks, or specialized vehicles, this wire harness offers flexibility—available in flexible or semi-rigid forms—and multiple color options such as red, black, blue, yellow, and green for easy identification and installation.

In electronics manufacturing, the Wire Harness Connector Assembly from LP serves as a crucial component in assembling prewired electrical cable harnesses for devices and machinery. This enables streamlined and organized wiring solutions that simplify installation, maintenance, and troubleshooting. The product’s adaptability to different packaging options, including polybag, opp bag, retail packaging, and customized packaging, further supports various production and distribution requirements.

Appliance manufacturers also benefit from the LP terminal wire harness’s robust design and high supply ability of up to 100,000 pieces, meeting the demands of large-scale production. Its minimum order quantity of 1000 PCS and competitive pricing at 0.0002 per unit make it an economical choice for OEMs and suppliers. With a delivery time frame of 7 to 10 days and flexible payment terms including T/T, Western Union, and L/C, LP ensures a reliable and efficient procurement process.

Industrial equipment applications require dependable and safe wiring solutions, which the LP Prewired Electrical Cable Harness effectively provides. Its excellent current carrying capability and material quality make it suitable for heavy-duty environments where electrical integrity is critical. Overall, the LP-TW010 Terminal Wire / Wire Harness is a versatile and dependable product designed to meet the demands of various industries, offering superior performance and customization options to fit any wiring scenario.

Customization:

Introducing the LP Terminal Wire / Wire Harness, model number LP-TW010, proudly made in China. Our product is certified with ISO-9001:2000, ensuring top-quality standards for every Terminal Cable Wire Assembly we deliver.

We offer a wide range of customization options to meet your specific needs. Available colors include Red, Black, Blue, Yellow, Green, and more. The wire gauge ranges from 10 AWG to 26 AWG, crafted from high-quality materials such as Copper, Aluminum, or Alloy to guarantee durability and optimal performance.

Our insulation materials include PVC, PE, Teflon, or Rubber, suitable for various applications including Automotive, Electronics, Appliances, and Industrial Equipment. Whether you require a High Voltage Wire Harness or an Industrial Wire Harness System, LP provides reliable and efficient solutions tailored to your requirements.

The minimum order quantity is 1000PCS with a competitive price of 0.0002 per piece. Packaging options are flexible, including polybag, opp bag, retail packaging, or customized packaging to fit your branding and logistical needs.

We maintain a strong supply ability of 100000PCS, ensuring timely delivery within 7 to 10 days. Payment terms are convenient and secure, accepting T/T, Western Union, and L/C.

Choose LP for your Terminal Cable Wire Assembly and experience superior quality, customization, and service excellence.

Support and Services:

Our Terminal Wire and Wire Harness products come with comprehensive technical support and services to ensure optimal performance and reliability. We provide detailed product specifications, installation guides, and troubleshooting assistance to help you integrate our wiring solutions seamlessly into your applications.

Our expert technical team is available to assist with custom design requests, compatibility checks, and to answer any questions regarding electrical ratings, environmental resistance, and mechanical durability. We also offer testing services to verify the quality and safety of the wire harness assemblies under various operating conditions.

For maintenance and repair, we provide guidelines on proper handling, inspection, and replacement procedures to extend the lifespan of your terminal wires and wire harnesses. Additionally, we supply documentation and certification to comply with industry standards and regulatory requirements.

Whether you require standard configurations or customized solutions, our support services are dedicated to ensuring your project’s success from design through deployment.

Packing and Shipping:

Our Terminal Wire and Wire Harness products are carefully packaged to ensure maximum protection during transit. Each wire harness is individually wrapped with anti-static and moisture-resistant materials to prevent damage from environmental factors.

We use sturdy, high-quality cartons with appropriate cushioning materials such as foam or bubble wrap to avoid any impact or deformation during shipping. For larger orders, the products are securely placed in reinforced boxes and palletized to maintain stability.

All packages are clearly labeled with product information, handling instructions, and shipping details to facilitate smooth delivery and inventory management.

Shipping is carried out through reliable logistics partners, offering options for express, standard, and bulk freight services to meet diverse customer requirements. We ensure timely dispatch and provide tracking information for every shipment.

Our commitment is to deliver Terminal Wire and Wire Harness products safely and promptly, maintaining their quality and functionality upon arrival.

![]()

-

Flexible Electrical Wire Harness Assembly With Or Without Shielding Designed For Automotive Industrial And Electronics Systems

-

Black Automotive Terminal Wire and Wire Harness Current Rating Up To 30A Perfect for Automotive Electrical Installations

-

Wire Gauge 10 AWG To 26 AWG Copper Automotive Wiring Harness Robust Electrical Harness Solutions For Automotive Industry

-

Blue Terminal Wire Wire Harness Flexible Or Semi Rigid With Or Without Shielding Ideal For Electrical Assembly Projects

-

Current Rating Up To 30A Terminal Cable Wire Assembly Length Typically 10cm To 5m Durable Electrical Connection Solutions

-

Shielding With Or Without Shielding Terminal Wire Wire Harness Suitable For Harsh Environments And Industrial Automation