|

|

Wire Gauge 10 AWG To 26 AWG Custom Wire Harness Solution With PE Insulation Material Engineered For And Electrical Wiring

Product Details:

Payment & Shipping Terms:

|

| Shielding: | Available With Or Without Shielding | Temperature Range: | -40°C To 105°C |

|---|---|---|---|

| Material: | Copper, Aluminum, Or Alloy | Insulation Material: | PVC, PE, Teflon, Or Rubber |

| Wire Gauge: | 10 AWG To 26 AWG | Voltage Rating: | 300V To 600V |

| Color: | Red, Black, Blue, Yellow, Green, Etc. | Connector Type: | Crimp, Solder, Or Plug-in |

| Terminal Wire: | 6.2mm Pitch Male/female Connector PVC Electronic Wire Industrial Equipment VLP Freezer Terminal Wire VL-3P Terminal Wire |

Product Description:

The Terminal Wire / Wire Harness product is a versatile and essential component designed to meet the diverse needs of various electrical and industrial applications. This product is engineered to provide reliable connectivity and efficient signal transmission, making it an ideal choice for those seeking a robust Custom Terminal Wire Assembly or a comprehensive Custom Wire Harness Solution. Whether you are working on automotive, aerospace, telecommunications, or industrial machinery, this wire harness system offers exceptional performance and durability.

One of the standout features of this Terminal Wire / Wire Harness product is the variety of connector types available. Customers can select from crimp, solder, or plug-in connectors, allowing for tailored connectivity options that suit specific installation requirements and preferences. Crimp connectors provide a secure and fast connection method, solder connectors ensure a permanent and highly conductive bond, while plug-in connectors offer ease of installation and maintenance. This flexibility in connector type supports a wide range of applications and enhances the overall adaptability of the wire harness system.

Shielding is another critical attribute of the Terminal Wire / Wire Harness product. It is available both with and without shielding, enabling users to choose the appropriate level of electromagnetic interference (EMI) protection based on their operational environment. Shielded wire harnesses are particularly beneficial in industrial settings where electrical noise can disrupt signal integrity, while unshielded versions are suitable for less demanding applications. The availability of shielding options underscores the product’s capability to serve as a reliable Industrial Wire Harness System in various conditions.

The material composition of the wires used in this product plays a crucial role in its overall performance. The Terminal Wire / Wire Harness is crafted from high-quality copper, aluminum, or alloy materials, each offering distinct advantages. Copper wires are renowned for their excellent electrical conductivity and durability, making them the preferred choice for most high-performance applications. Aluminum wires provide a lightweight alternative, ideal for situations where weight reduction is critical without compromising conductivity. Alloy materials combine the strengths of multiple metals to deliver enhanced mechanical and electrical properties, ensuring optimal performance in demanding environments.

Flexibility is a vital consideration in wire harness design, and this product excels by offering both flexible and semi-rigid options. Flexible wire harnesses allow for easier installation in tight spaces and complex assemblies, enabling smooth routing and bending without damaging the wires. Semi-rigid wire harnesses provide added structural integrity, making them suitable for applications where the harness needs to maintain a specific shape or resist deformation. This range of flexibility ensures that the Terminal Wire / Wire Harness can adapt to a wide variety of design challenges and application requirements.

Temperature resistance is another key feature of this product, with an operational range from -40°C to 105°C. This broad temperature tolerance makes the wire harness suitable for use in harsh environments, including extreme cold and elevated heat conditions. Whether deployed in outdoor industrial machinery exposed to the elements or in automotive systems subjected to engine heat, the Terminal Wire / Wire Harness maintains reliable performance and longevity. This temperature range also ensures compliance with industry standards for safety and durability.

In summary, the Terminal Wire / Wire Harness product offers a comprehensive and customizable solution for anyone in need of a dependable Custom Terminal Wire Assembly or an advanced Custom Wire Harness Solution. Its diverse connector options, shielding availability, premium material selection, flexibility variants, and wide temperature range collectively make it an outstanding choice for an Industrial Wire Harness System. By choosing this product, customers can expect enhanced electrical performance, improved installation efficiency, and long-lasting durability tailored to their specific application needs.

Features:

- Product Name: Terminal Wire / Wire Harness

- Custom Wire Harness Solution tailored to your needs

- Available With Or Without Shielding for enhanced protection

- Temperature Range: -40°C To 105°C suitable for various environments

- Insulation Material options include PVC, PE, Teflon, Or Rubber

- Flexibility: Choose between Flexible Or Semi-Rigid designs

- Color options: Red, Black, Blue, Yellow, Green, Etc.

- Ideal for Terminal Cable Wire Assembly applications

- Supports High Voltage Wire Harness requirements

Technical Parameters:

| Voltage Rating | 300V To 600V |

| Wire Gauge | 10 AWG To 26 AWG |

| Shielding | Available With Or Without Shielding |

| Material | Copper, Aluminum, Or Alloy |

| Insulation Material | PVC, PE, Teflon, Or Rubber |

| Temperature Range | -40°C To 105°C |

| Current Rating | Up To 30A |

| Color | Red, Black, Blue, Yellow, Green, Etc. |

| Length | Customizable, Typically 10cm To 5m |

| Flexibility | Flexible Or Semi-Rigid |

Applications:

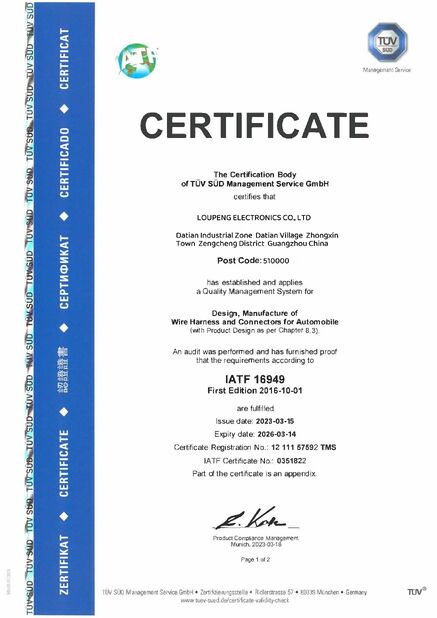

The LP Terminal Wire / Wire Harness (Model Number: LP-TW004) is an essential component widely used across various industries due to its high quality and versatility. Originating from China and certified with ISO-9001:2000, this product ensures reliable performance and adherence to international standards. With a minimum order quantity of 1000PCS and a competitive price of 0.0002 per piece, it is an ideal choice for businesses seeking affordable yet dependable wiring solutions.

The Multi Terminal Wire Harness offered by LP is designed to meet the demanding requirements of automotive, industrial, and electronic applications. Its flexibility—available in both flexible and semi-rigid forms—along with a wire gauge range from 10 AWG to 26 AWG, allows it to be tailored precisely to specific project needs. The wire harness can be constructed using copper, aluminum, or alloy materials, ensuring excellent conductivity and durability.

One of the primary application occasions for the LP-TW004 is in the automotive sector, where the Automotive Wiring Harness plays a critical role in vehicle electrical systems. It is used for connecting various electrical components such as sensors, lights, and control units, ensuring seamless communication and power distribution throughout the vehicle. The availability of multiple colors—Red, Black, Blue, Yellow, Green, and more—facilitates easy identification and organization of wires within complex assemblies.

Beyond automotive uses, the Custom Wire Harness Solution provided by LP is widely utilized in industrial machinery, home appliances, and communication devices. Its customizable length, typically ranging from 10cm to 5m, and packaging options including polybag, opp bag, retail, or customized packaging, make it highly adaptable to diverse project requirements. The efficient delivery time of 7 to 10 days, combined with flexible payment terms such as T/T, Western Union, and L/C, further supports quick and convenient procurement processes.

Overall, the LP Terminal Wire / Wire Harness LP-TW004 is designed for durability, adaptability, and ease of installation, making it a preferred choice for manufacturers and engineers needing a reliable wiring solution. Whether you require a multi terminal wire harness for automotive systems or a custom wire harness solution for specialized equipment, LP’s product delivers exceptional performance and support across various application scenarios.

Customization:

Introducing the LP Terminal Wire / Wire Harness, model number LP-TW004, proudly made in China and certified under ISO-9001:2000 standards. This product is designed to meet the highest quality requirements for Automotive Wiring Harness, Terminal Cable Wire Assembly, and Prewired Electrical Cable Harness applications.

With a supply ability of 100,000PCS and a minimum order quantity of 1000PCS, we offer competitive pricing at $0.0002 per unit. Our packaging options include polybag, opp bag, retail packaging, or customized packaging to suit your specific needs.

The LP-TW004 Terminal Wire / Wire Harness features flexible or semi-rigid construction, with connector types available as crimp, solder, or plug-in. It supports a current rating of up to 30A and wire gauges ranging from 10 AWG to 26 AWG. Additionally, shielding is available with or without shielding to ensure optimal performance and protection.

We guarantee a delivery time of 7 to 10 days, with payment terms including T/T, Western Union, and L/C for your convenience. Trust LP for reliable, high-quality Terminal Cable Wire Assemblies and Prewired Electrical Cable Harness solutions tailored to your automotive wiring harness needs.

Support and Services:

Our Terminal Wire and Wire Harness products are designed to meet the highest standards of quality and reliability. We provide comprehensive technical support to assist you with product selection, installation, and troubleshooting to ensure optimal performance in your applications.

Our services include detailed product documentation, application guidance, and custom configuration options to tailor the wire harnesses to your specific requirements. We also offer testing and validation support to guarantee compliance with industry standards and customer specifications.

For installation support, we provide step-by-step instructions and best practices to enhance efficiency and reduce the risk of errors. In case of technical issues, our experienced support team is available to help diagnose problems and recommend effective solutions.

Additionally, we offer training sessions and webinars to keep your team updated on the latest technologies and techniques related to Terminal Wire and Wire Harness products. Our goal is to ensure that you receive the highest level of service and support throughout the lifecycle of our products.

Packing and Shipping:

Each Terminal Wire / Wire Harness is carefully packaged to ensure protection during transit. The products are first placed in anti-static bags or protective sleeves to prevent damage from dust, moisture, and static electricity. These are then securely packed in sturdy cardboard boxes with adequate cushioning materials such as foam or bubble wrap to absorb shocks and vibrations.

For bulk orders, the wire harnesses are organized and bundled neatly, labeled for easy identification, and placed in larger cartons or wooden crates depending on the quantity and size. All packages are sealed tightly and clearly marked with handling instructions and shipping labels.

We work with reliable shipping partners to deliver products promptly and safely to your destination. Tracking information is provided to keep you updated on the shipment status. Our packaging and shipping processes are designed to ensure that the Terminal Wire / Wire Harness arrives in perfect condition, ready for immediate use.

![]()

-

Flexible Electrical Wire Harness Assembly With Or Without Shielding Designed For Automotive Industrial And Electronics Systems

-

Black Automotive Terminal Wire and Wire Harness Current Rating Up To 30A Perfect for Automotive Electrical Installations

-

Wire Gauge 10 AWG To 26 AWG Copper Automotive Wiring Harness Robust Electrical Harness Solutions For Automotive Industry

-

Blue Terminal Wire Wire Harness Flexible Or Semi Rigid With Or Without Shielding Ideal For Electrical Assembly Projects

-

Current Rating Up To 30A Terminal Cable Wire Assembly Length Typically 10cm To 5m Durable Electrical Connection Solutions

-

Shielding With Or Without Shielding Terminal Wire Wire Harness Suitable For Harsh Environments And Industrial Automation