|

|

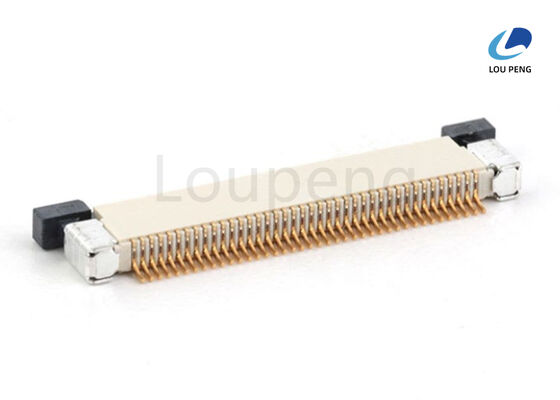

Gold Plating Contact Resistance 20max FPC FFC Connector Tin Plated Solder Tab Phosphor Bronze Providing Signal Transmission

Product Details:

Payment & Shipping Terms:

|

| Mounting Type: | Surface Mount Technology (SMT) / Through Hole Technology (THT) | Current Rating: | 0. 5Amps |

|---|---|---|---|

| Max Processing Temp: | 230°C For 30~60 Seconds, (260°Cfor 10 Seconds) | Plating: | Gold Plating / Tin Plated |

| Contact Resistance: | 20max. | Pitch: | 0.5mm / 1.0mm / 1.25mm / 1.27mm |

| Dielectric Withstanding: | AC 500V | Contact Material: | Copper Alloy / Phosphor Bronze |

Product Description:

The FPC / FFC Connector is an essential component designed to provide reliable and efficient connections in various electronic applications. Commonly referred to as an FPC Board to Board Connector, Flat Flexible Cable Connector, or Flat Printed Cable Connector, this product plays a critical role in establishing seamless electrical connectivity between flexible printed circuits and other electronic modules. With its robust construction and high-performance characteristics, it is widely used in industries ranging from consumer electronics to automotive and industrial equipment.

One of the key features of this connector is its impressive dielectric withstanding capability, rated at AC 500V. This attribute ensures that the connector can withstand high voltage stress without breakdown, making it highly reliable for use in circuits that require strong insulation and safety standards. The dielectric strength is a crucial factor in preventing electrical shorts and ensuring long-term operational stability, which is essential for maintaining the integrity of sensitive electronic devices.

The contact material used in this FPC / FFC Connector is a high-quality copper alloy or phosphor bronze. Both materials are known for their excellent electrical conductivity and mechanical strength. Phosphor bronze, in particular, offers superior spring properties and resistance to wear and corrosion, which guarantees consistent contact pressure and reliable signal transmission over extended periods. This ensures minimal contact resistance, which is specified at a maximum of 20 milliohms, thereby supporting efficient electrical performance with minimal signal loss or interference.

The locker's material is made from PPS (Polyphenylene Sulfide), which meets the stringent UL94V-0 flammability rating. This means the connector's locking mechanism is not only durable but also flame-retardant, adding an extra layer of safety to the overall design. The use of PPS complies with RoHS directives, ensuring that the connector is environmentally friendly and free from hazardous substances. This compliance is particularly important for manufacturers aiming to meet global environmental standards and reduce the ecological impact of electronic components.

In terms of aesthetics and practical design, the FPC / FFC Connector is available in two color options: gray and black. These color choices allow for easy identification and integration into various device designs, enhancing the overall assembly process. The compact and streamlined design of the connector also facilitates space-saving layouts in densely packed electronic assemblies, making it an ideal choice for modern, miniaturized electronic devices.

The versatility of this Flat Flexible Cable Connector makes it suitable for a wide range of applications. It is extensively used in connecting LCD displays, touch panels, cameras, and other peripheral modules to main circuit boards. The FPC Board to Board Connector design supports easy installation and removal, which is beneficial during assembly, maintenance, and repair operations. Its reliable contact mechanism ensures stable electrical connections even in environments subject to vibrations and mechanical stress.

Furthermore, the Flat Printed Cable Connector's high contact reliability and robust construction contribute to longer device lifespans and reduced downtime. By minimizing connection failures and ensuring consistent signal integrity, this connector helps enhance overall device performance and user experience. Its compatibility with various FPC and FFC types allows it to cater to diverse design requirements, making it a versatile component in the electronics manufacturing industry.

In summary, the FPC / FFC Connector is a high-quality, durable, and reliable solution for connecting flexible printed circuits within electronic devices. Its excellent dielectric withstanding capacity, superior contact materials, flame-retardant locking mechanism, and environmental compliance make it an ideal choice for manufacturers seeking dependable and safe connectors. Whether used as an FPC Board to Board Connector, Flat Flexible Cable Connector, or Flat Printed Cable Connector, this product delivers outstanding performance, ease of use, and adaptability to meet the demanding needs of modern electronic applications.

Features:

- Product Name: FPC / FFC Connector

- Flexible Printed Circuit Connector designed for reliable connections

- Interface type: Flexible Flat Cable Interface (FFC)

- Locking Material: PPS UL94V-0 compliant and RoHS certified

- Insulation Material: LCP (Liquid Crystal Polymer) / Nylon 6T, UL94V-0 rated and RoHS compliant

- Durability: Supports up to 20,000 mating cycles for long-lasting performance

- Dielectric Withstanding Voltage: AC 500V for enhanced safety

- Current Rating: 0.5 Amps suitable for low power applications

- Ideal for applications requiring a Flexible Flat Cable Interface

Technical Parameters:

| Operating Temperature | -40°C To +105°C |

| Connector Type | ZIF / LIF |

| Dielectric Withstanding Voltage | AC 500V |

| Mounting Type | Surface Mount Technology (SMT) / Through Hole Technology (THT) |

| Insulator Resistance | 500Megohms Min. |

| Durability | Up To 20,000 Mating Cycles |

| Lockeer Material | PPS UL94V-0 RoHS Compliant |

| Pitch | 0.5mm / 1.0mm / 1.25mm / 1.27mm |

| Contact Material | Copper Alloy / Phosphor Bronze |

| Maximum Processing Temperature | 230°C For 30~60 Seconds, (260°C for 10 Seconds) |

Applications:

The LP-FPC021 is a high-quality FPC Board to Board Connector designed and manufactured in China, proudly bearing the ISO-9001:2000 certification to guarantee reliable performance and durability. This connector is an excellent choice for a variety of electronic applications where a secure and efficient connection between flexible printed circuit (FPC) boards is essential. With a minimum order quantity of 1000PCS and a competitive price of 0.03 per unit, it offers great value for manufacturers and developers looking for cost-effective yet high-performance solutions.

Featuring insulation materials such as Liquid Crystal Polymer (LCP) and Nylon 6T UL94V-0, the LP-FPC021 ensures excellent heat resistance and flame retardance, complying with RoHS standards for environmental safety. This makes it ideal for use in modern electronic devices that demand both safety and reliability. The connector type is available in both ZIF (Zero Insertion Force) and LIF (Low Insertion Force) configurations, providing flexibility in design and ease of use during assembly.

Common application occasions for the LP-FPC021 FPC Board to Board Connector include consumer electronics such as smartphones, tablets, and wearable devices, where compact and reliable connections are critical. It is also widely used in medical equipment, automotive electronics, and industrial automation systems, where the need for secure and durable interconnects is paramount. The product’s dielectric withstanding voltage of AC 500V and a maximum contact resistance of 20 milliohms ensure stable electrical performance under demanding conditions.

In various scenarios such as prototyping, small-scale production, or large-volume manufacturing, the LP-FPC021 is a versatile choice. Its packaging in reels or tubes facilitates efficient handling and automated assembly lines. The supply ability of 100,000PCS with a delivery time of 8 to 12 days enables manufacturers to meet tight production schedules without compromising quality. Payment terms include T/T, Western Union, and L/C, accommodating diverse business requirements.

Sample units are also available free of charge, allowing engineers and designers to test and evaluate the connector before committing to bulk purchases. Whether for connecting flexible printed circuits in compact handheld devices or interfacing complex multi-layer boards in industrial systems, the LP-FPC021 FPC Electronic Connector Type is engineered to deliver reliable, high-performance connections. Its robust design and certification-backed quality make it a preferred solution for a wide range of electronic applications requiring dependable FPC Board to Board Connector solutions.

Customization:

LP proudly presents the LP-FPC021, a high-quality FPC Board to Board Connector designed to meet diverse customization needs. Manufactured in China and certified with ISO-9001:2000, this connector ensures reliability and superior performance for your electronic applications.

Our FFC Flexible Circuit Connector features an insulator made from premium LCP (Liquid Crystal Polymer) or Nylon 6T UL94V-0 RoHS compliant materials, providing excellent insulation with a minimum insulator resistance of 500 Megohms. The solder tab is crafted from durable phosphor bronze, ensuring secure and stable connections.

The LP-FPC021 supports a pitch range of 0.5mm, 1.0mm, 1.25mm, and 1.27mm, accommodating 2 to 50 pins to suit various design requirements. We offer packaging options including reels and tubes for convenient handling and assembly.

With a minimum order quantity of 1000PCS and a competitive price of $0.03 per piece, our supply ability reaches up to 100,000PCS, ensuring timely fulfillment of your orders. Delivery time ranges from 8 to 12 days, with flexible payment terms such as T/T, Western Union, and L/C.

Choose LP's FFC Flexible Circuit Connector for your next project to experience superior quality, efficient delivery, and customizable solutions tailored to your FPC Board to Board Connector needs.

Support and Services:

Our FPC/FFC Connectors are designed to provide reliable and high-performance connections for flexible printed circuits and flexible flat cables in various electronic applications. To ensure optimal performance and longevity of the connectors, it is important to follow proper handling, installation, and maintenance procedures.

When handling FPC/FFC connectors, avoid applying excessive force or bending the connector beyond its specified mechanical limits. Always use appropriate tools and follow the recommended insertion and extraction techniques to prevent damage to the contacts or the connector housing.

During installation, ensure that the flexible circuit or cable is properly aligned with the connector. Secure the cable firmly without over-tightening, which could damage the conductor paths. Confirm that the locking mechanism, if present, is fully engaged to maintain a stable connection.

For maintenance, periodically inspect the connectors for signs of wear, contamination, or corrosion. Clean the contacts gently using approved cleaning agents and tools to maintain electrical integrity. Avoid exposure to harsh environmental conditions that exceed the connector's specified operating temperature and humidity ranges.

If you experience any issues with your FPC/FFC connectors, consult the product datasheet and installation guides for troubleshooting tips. For specialized support, professional services are available to assist with custom configurations, testing, and quality assurance to meet your specific application requirements.

Packing and Shipping:

Product Packaging and Shipping for FPC / FFC Connector

Our FPC / FFC connectors are carefully packaged to ensure their safety and integrity during transit. Each connector is individually placed in anti-static packaging to prevent damage from electrostatic discharge.

The connectors are then organized into trays or reels, depending on the product specifications and customer requirements, to maintain their structure and prevent deformation.

These trays or reels are securely packed into sturdy cardboard boxes with adequate cushioning materials to absorb shocks and vibrations during shipping.

For bulk orders, multiple boxes are consolidated into larger cartons or pallets, ensuring efficient handling and minimizing the risk of damage.

We offer various shipping options including air freight, sea freight, and express courier services, allowing customers to choose the most suitable method based on urgency and budget.

All shipments are carefully labeled with product details, handling instructions, and shipping information to facilitate smooth customs clearance and delivery.

Tracking information is provided promptly after dispatch, enabling customers to monitor their orders until arrival.

Our packaging and shipping processes comply with international standards to guarantee that the FPC / FFC connectors reach customers in perfect condition and ready for immediate use.

![]()

-

0.5mm Pitch Flexible Printed Circuit Connector Durable Up To 20 Cycles Connection Solutions for Electronic Assemblies and Devices

-

Phosphor Bronze Solder Tab FPC FFC Connector 2 To 50 Pins Flexible Printed Circuit Cable Connector Electrical Connection

-

Gray FPC FFC Connector Flexible Flat Cable Connector Suitable for Compact Electronic Devices and Industrial Applications

-

Nylon 6T UL94V0 Insulation Material Flat Flexible Cable Connector Featuring Phosphor Bronze Solder Tab RoHS Certified Long Lasting

-

Copper Alloy Contact Material FPC Ribbon Cable Connector Durable Flexible Flat Flexible Printed Circuit Connector for Electronic Devices

-

PPS UL94V0 RoHS FFC Flexible Flat Cable Connector 0.5Amps Current Rating Electrical Connection for Industrial Applications